Dr. E. Horn will present a couple of new products on this year’s SMM: a new Oil Mist Detector »Ammonia-Ready«, a Water in Oil Sensor System in multiple alignment with control of up to eight sensors, and a Bearing Monitoring System with new Module Type Package (MTP) interface software. Finally, Dr. E. Horn will present their brand-new CLDM-System:

In two-stroke engines, the wear condition of the cylinder liners is an important parameter to assess the operating conditions of the engine. The quantity and effectiveness of the cylinder oil as well as possible corrosion conditions in the liner have a significant influence on wear and operating cost.

Timely intervention is required here. Usually, this wear can only be detected by manual measuring of the diameter using an inside micrometre. However, such a measurement is only possible approximately every three years because the cylinder head has to be removed and the piston is drawn. Such period is too long to detect relevant changes in the wear status in good time. In addition, these manual measurements may have inaccuracies because the correct handling of an inside micrometre requires a lot of experience.

In order to be informed of a change in the wear status at shorter intervals and therefore in good time, a measurement can be carried out by a shore-based service company. A special device is used, which is placed through the scavenging air ports on the top of the piston. It determines the liner diameter either mechanically by tactile means or optically by laser. Such service is expensive and can only be carried out in certain harbours. An ad-hoc inspection is not possible under these circumstances.

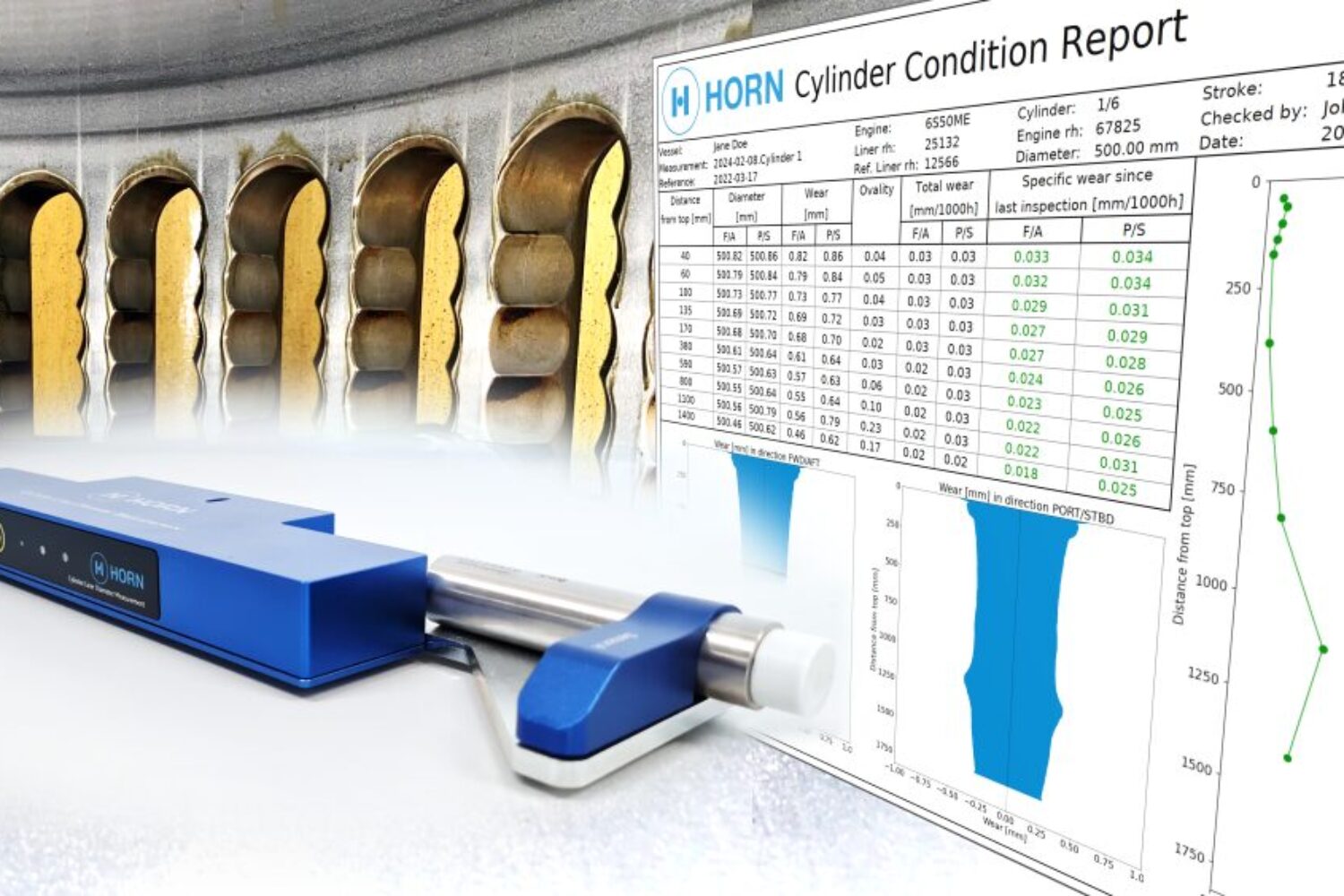

The new Dr. Horn solution: Control at any time. The robust and easy-to-use CLDM »Blue-spy« system was developed on the basis of the highly sensitive distance sensors produced by Dr. Horn, which are in service in thousands of bearing monitoring systems.

The CLDM »Blue-spy« enables the crew to carry out wear measurements themselves at any time. The device is also placed on the piston top by passing it through the scavenging air ports. Then the engine is to be turned and the data are recorded.

The results are evaluated and documented automatically in accordance with the engine manufacturer’s specification. Due to the favourable pricing of the CLDM »Blue-spy« the amortisation period is less than two years. Now the crew can carry out liner wear measurements as often as needed – routinely or on an ad-hoc basis at any time.

Hall A3 | booth 238