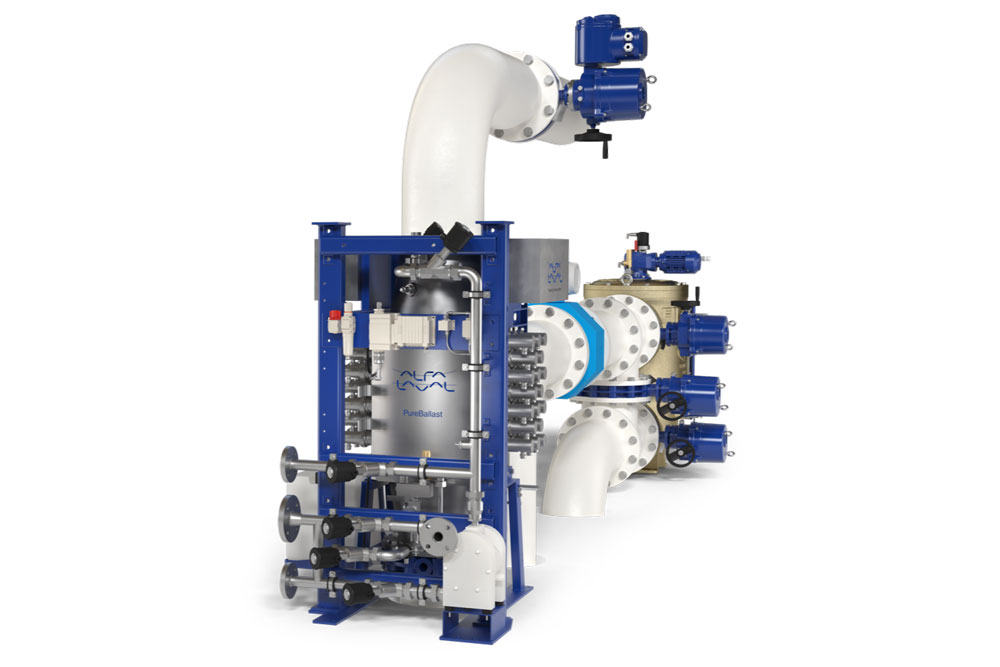

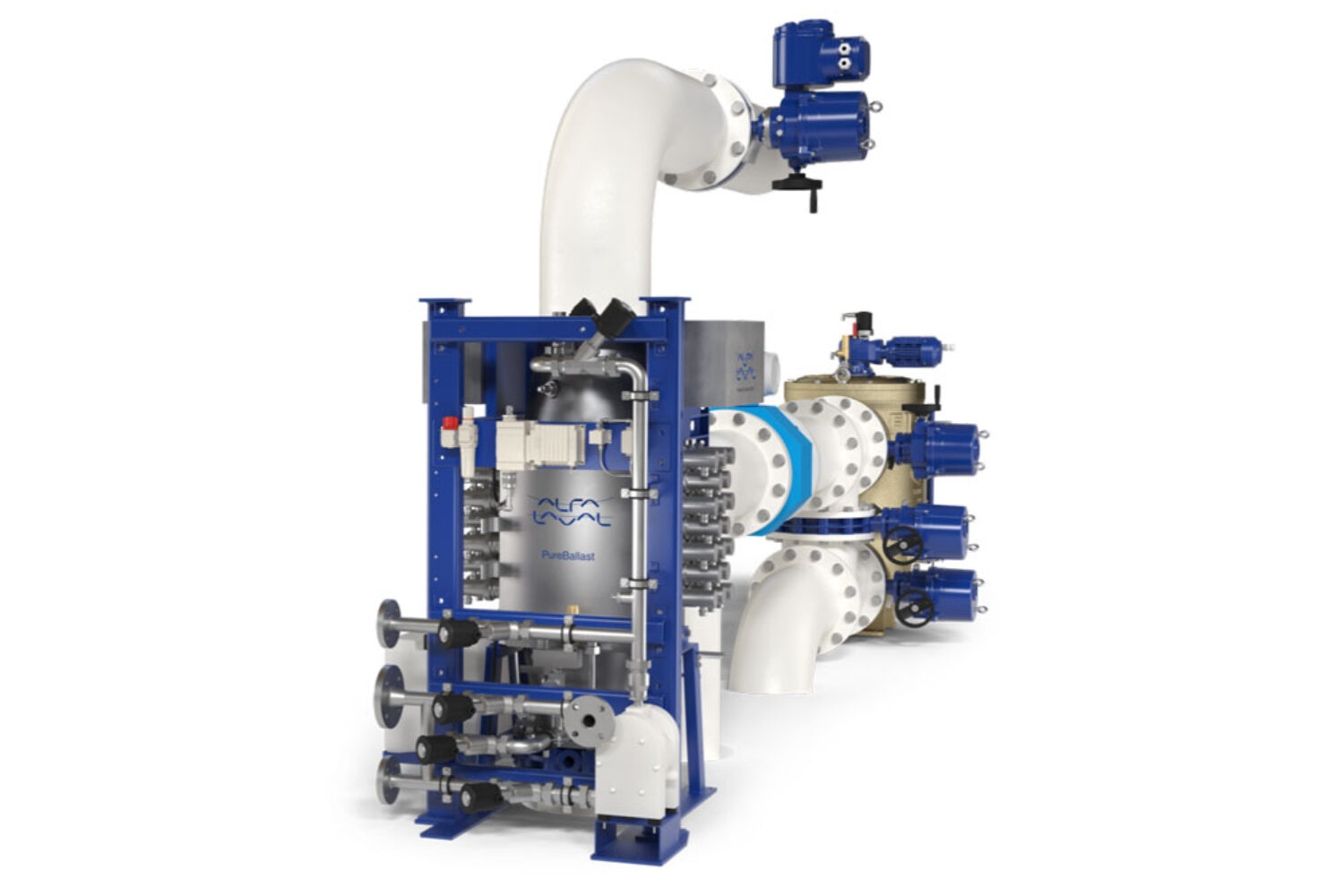

Easier installation, reduced energy consumption and better performance – this is what Alfa Laval promises for its new PureBallast 3 Ultra ballast water management system.

The new ballast water management system (BWMS) is based on the proven PureBallast 3 technology. According to Alfa Laval, the system offers new benefits for the “most efficient UV treatment solution on the market, from improved performance in challenging waters to further energy savings and easier installation”. Deliveries of PureBallast 3 Ultra are scheduled to start in Q3 2025.

As the retrofit market slows down, many manufacturers have withdrawn from the BWMS market or face an uncertain future, according to Alfa Laval. Alfa Laval, on the other hand, is “continuing to develop its leading UV technology and offering for shipowners and shipyards”.

Alfa Laval has more than 3,000 systems on the market

“PureBallast 3 Ultra shows that Alfa Laval is here to stay,” says Peter Sahlén, Head of Alfa Laval PureBallast. “The advances build on 20 years of experience and the thousands of PureBallast 3 systems delivered, more than 3,000 of which are supported by our PureBallast Compliance Service Package.”

For shipowners working in sediment-rich areas, PureBallast 3 Ultra is designed to provide additional safety. The system offers improved performance in challenging waters thanks to a new filter design that reduces the risk of filter blockages. Some of the filter improvements, such as a faster gear motor that improves backwash efficiency, are also available as upgrades to existing PureBallast 3 systems.

The new filter design ensures ship operation, especially in combination with Alfa Laval’s efficient UV technology, says the manufacturer. PureBallast 3 Ultra runs at only 50% of its potential operating capacity in many conditions, but can be ramped up to full capacity to maintain flow in difficult waters.

Reduced energy consumption

Because PureBallast 3 Ultra supports higher flow rates, it consumes less energy relative to the amount of ballast water than competing UV systems. Thanks to an expanded range of UV reactor sizes that are precisely matched to the ballast pump capacity, PureBallast 3 Ultra can also be more efficient than previous systems. At certain flow rates, power requirements are reduced by almost 20%, the company says.

The wider choice of UV reactors means more flexibility for yards, which also benefit from other features. The CIP (Cleaning-In-Place) unit and pressure monitoring device are integrated into the UV reactor module, and the improved filter design is smaller. With a small footprint and fewer connections, PureBallast 3 Ultra can be configured for ballast water flows of 42-3,000 m3/h as well as for Ex requirements.

The BWMS manufacturer further announces that Alfa Laval’s production facility in Qingdao, China, will provide shipyard support and smooth deliveries of PureBallast 3 Ultra from the third quarter of 2025.