WinGD is expecting to secure the majority of dual-fuel engine orders for LNG carriers being built in the second phase of QatarEnergy’s newbuilding project.

With initial engine and technical specifications confirmed for nearly half of the orders in the second round, WinGD’s X-DF2.0 engines are already the preferred choice to be installed on most vessels.

Initial decisions on the remaining vessels will be made shortly by QatarEnergy, which will operate the gas carriers under long-term charters. The early support for WinGD’s latest X-DF technologies follows strong orders in the initial phase of newbuilding last year when shipowners chartering to QatarEnergy ordered 25 vessels powered by the low-pressure, dual-fuel two-stroke engines. Based on initial decisions, that number will be exceeded in the second phase.

WinGD Director Sales, Volkmar Galke said: “QatarEnergy, shipyards and owners were clear in their endorsement of X-DF in the last round of the project. We are confident that our latest efficiency technologies allow us to build on that success in the current round. Alongside our well-established engine platform, these technologies have provided a further point of difference for WinGD’s offering, increasing the lead over other engine concepts.”

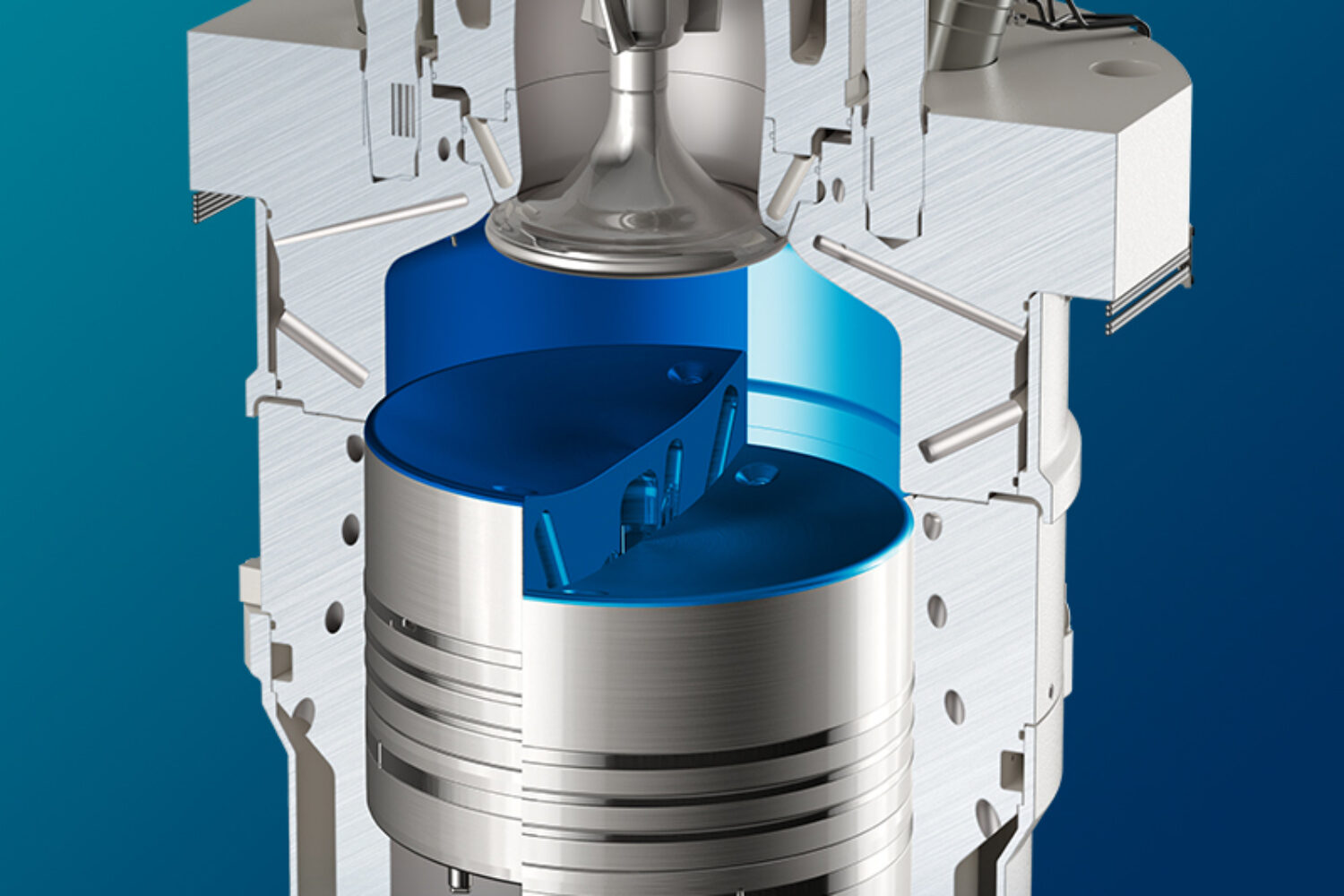

Among the new improvements to X-DF, last June, WinGD introduced Variable Compression Ratio (VCR) technology, a simple hydraulic solution that optimises engine compression ratio, dependent on the fuel used and engine load. When added to X-DF engines, VCR provides fuel and emissions savings in both gas and diesel modes, supporting operators’ ability to select the most economically attractive fuel.

On-engine iCER technology, a compact combustion control solution delivering emissions and fuel efficiency improvements, was adopted by several LNG carriers in the first round, just months after the technology was introduced. This year, the on-engine configuration has been available from the start of the ordering phase and has already been selected for some vessels.