Methanol is gaining ground as an alternative fuel. Against this backdrop, the Swedish company Alfa Laval reports more than 100 orders for its FCM methanol fuel system.

The shipping industry is undergoing a transition towards decarbonisation, and methanol has emerged as the preferred alternative fuel for many shipowners when ordering new vessels, Alfa Laval states. According to the Methanol Institute, over 250 new methanol-capable ships have been ordered worldwide to date. In addition, methanol is the most frequently ordered alternative fuel type in 2023, which underlines its growing acceptance, says Alfa Laval. [ds_preview]

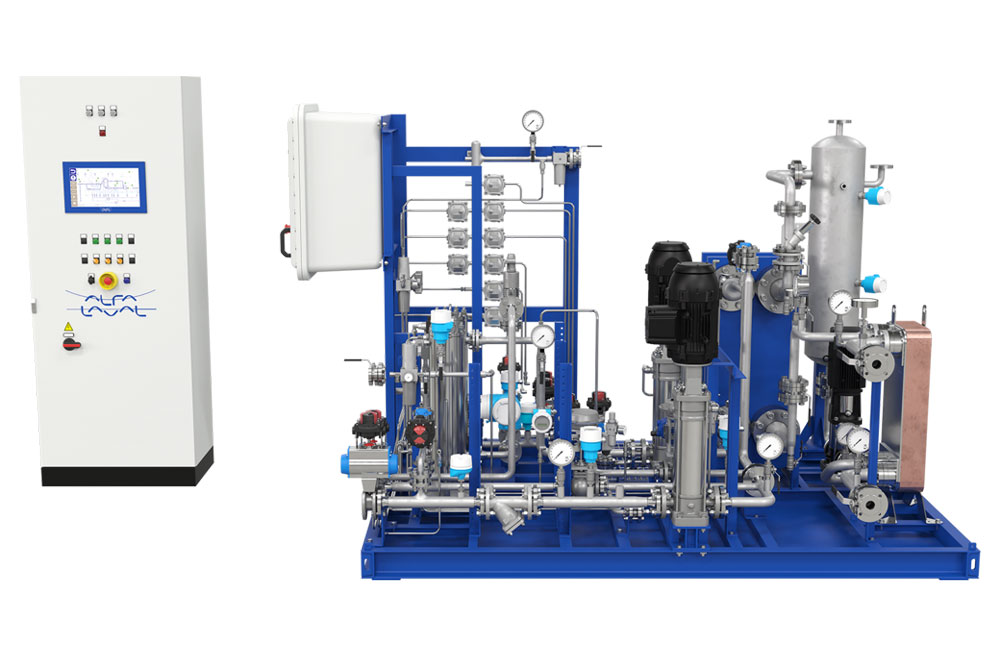

Alfa Laval is benefiting from this development and has now booked more than 100 orders for its low flashpoint fuel supply system (LFSS) – FCM Methanol. Launched in 2015, the system has the longest operating experience on the market, with over 450,000 hours at sea, according to Alfa Laval.

“Our journey to this point would not have been possible without valuable partnerships with engine builders, shipyards and good cooperation with shipowners who are pioneers in the introduction of alternative fuels,” says Viktor Friberg, Head of Marine Separation & Fuel Supply Systems, Alfa Laval. “Together, we will continue to develop fuel treatment solutions for alternative fuels and support the shipping industry in achieving climate targets.”

Third generation of FCM methanol at the start

Alfa Laval is already working on the third generation of its FCM system, and the latest generation of this solution is being used in recent orders, according to the manufacturer. The first ships equipped with this system are about to undergo their second inspection in dry dock.

Thanks to years of experience, Alfa Laval says it has been able to build a robust support system around methanol. A global network of fully trained and equipped marine service personnel ensures maximum system uptime for its customers. To ensure efficient operation and maximum engine protection, Alfa Laval has developed special service kits for optimised FCM maintenance. In order to be geographically closer to its global customer base, production and the supply chain have also been expanded to cover the whole of Europe and, more recently, China.

Cooperation with MAN and WinGD

Alfa Laval FCM Methanol not only secures orders for new plants, but is also involved in innovative projects. One example of this is the selection for the industry’s first methanol retrofit project for a Maersk container ship. Similar projects are also being discussed with other shipping companies. Even if reaching 100 orders is a significant success, the development continues, says the manufacturer. For example, Alfa Laval is actively working with MAN Energy Solutions to develop a fuel supply system for 4-stroke engines. The company is also working with WinGD to soon provide an ammonia solution for 2-stroke engines.