MAN Energy Solutions’ largest service centre, MAN PrimeServ, is creating a repair and conversion concept for the future. This includes dealing with new fuels, machines, and technologies in response to the market’s challenges.

The MAN PrimeServ Hamburg site is located in the heart of the port. Here, 300 employees specialise in the repair and maintenance of two- and four-stroke marine engines and turbomachinery on an operating area of around 30,000 m2.

To adapt to changes in the maritime service industry, such as alternative fuels, larger ships and shorter port calls, MAN PrimeServ has announced changes to its core concept. Most of the work will shift to the service workshop and components, and PrimeServ employees will travel to the ships’ berths to work onsite.

MAN PrimeServ specialises in repair technologies

“Our Hamburg site has developed its own concept to meet these new market trends. Accordingly, our service workshop is being expanded and is now specialising in repair technologies,” says Stefan Eefting, Senior Vice President and Head of MAN PrimeServ Germany. The future lies in new welding technologies, the in-situ machining of components and the extension of their service life – and, of course, in the associated reduction in CO2 emissions compared to the production of a new part.

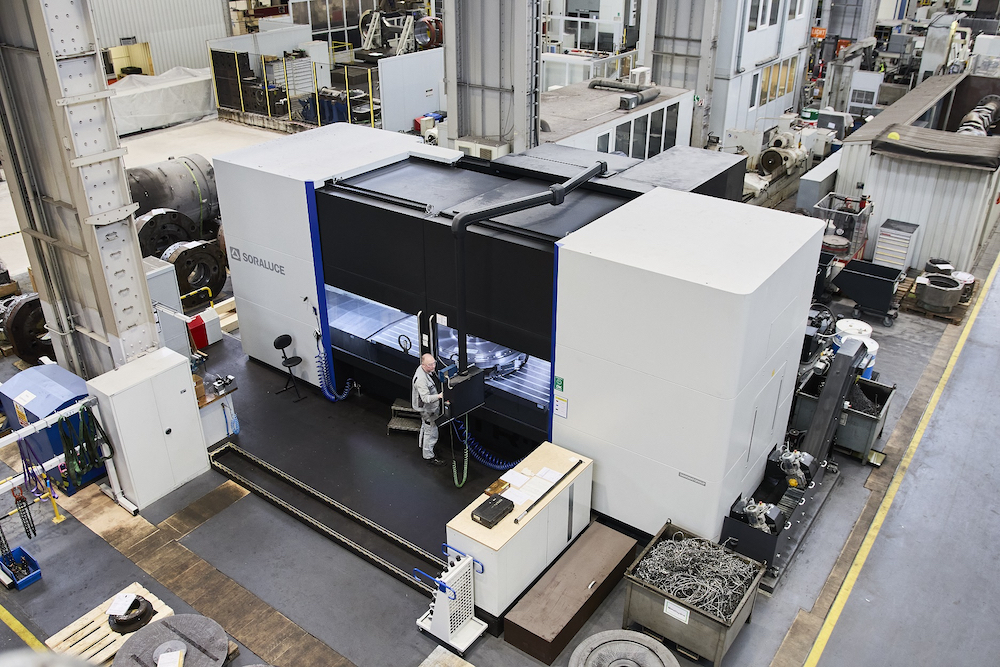

“Our investments in new machines for machining components include a machining centre that reduces the machining time for certain components such as piston crowns, cylinder covers, flywheels and counterweights for crankshafts by a factor of four,” emphasises Olaf Gunia, Head of MAN PrimeServ Hamburg. These reduced processing times should contribute to shorter port calls of the ships and lower costs, which will, of course, be passed on to the customers.”

Conversion of diesel engines to dual-fuel technology

Another new field of activity for Hamburg is the conversion of diesel engines to dual-fuel technology by service technicians in Hamburg and with the help of MAN PrimeServ’s international network if travel is required. Such projects require complex planning, not only in terms of technicians and tools, but also in terms of shipping components abroad to the respective ships.

“We prepare for the conversion, procure the necessary tools and train employees to handle the new fuels,” adds Gunia. “Recruiting qualified personnel is currently a challenge, but we are continuously expanding our workforce with experienced engineers and skilled workers such as machinists, welders and machining technicians. New times call for new approaches and I am convinced that PrimeServ Hamburg is well positioned for the future.”

![Red_MAN_Halle_2024_042[46] Kopie A Soraluce machine for milling, drilling, turning and grinding components at PrimeServ Hamburg.](/wp-content/uploads/elementor/thumbs/Red_MAN_Halle_2024_04246-Kopie-qty71xbl1x8mpmbo2t0bprj5cdvhpzom8q8y3lpeds.jpg)