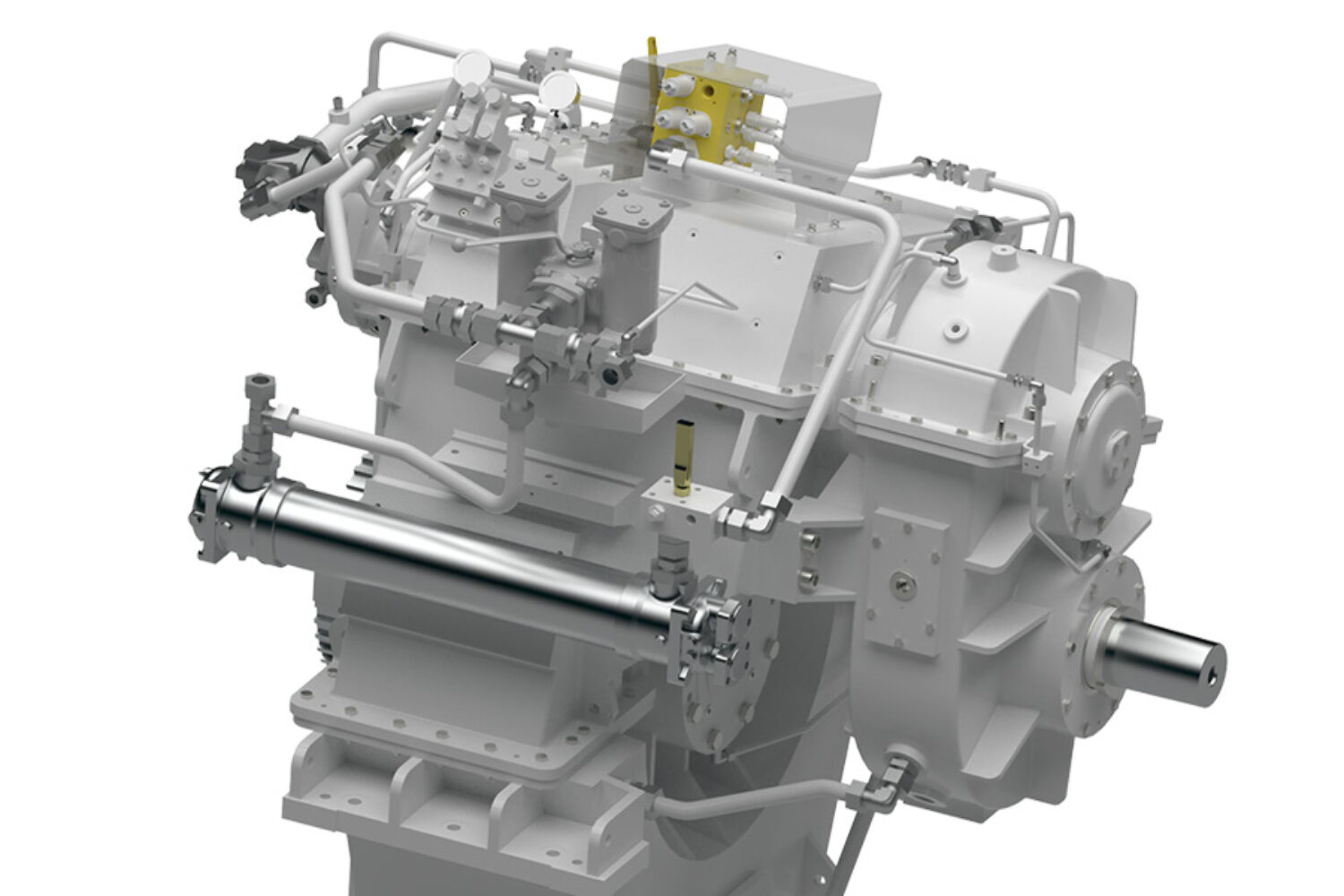

With Bachmann’s support, REINTJES GmbH, based in Hameln, Germany, has developed an automated marine reverse transmission that precisely regulates hydraulic pressure on the clutch plates and facilitates smooth gear shifting.

Based on Bachmann’s M200 control system, REINTJES developed the ‘Gearbox-Automation (GBX-A)’, a modular system that automatically optimizes the coupling process, thus enabling a more protective mode of operation.

How the control lever is operated – in simple terms, whether it is moved quickly or more moderately – determines the shift characteristics automatically selected by the GBX-A. This kind of situational gear shifting has the advantage that, during normal operations, it is the only way to maximize smooth engagement of the clutch – that is also gentle on the transmission.

“In dangerous situations, of course, the clutch is engaged without delay, which won’t immediately damage the system, but is not system-friendly – you wouldn’t want to drive like that every day,” explains Norman Klippel, Technical Subproject Manager Automation at REINTJES.

Modular gearbox

The GBX-A has a modular design and can be configured via predefined parameters. The Bachmann OT1200 terminal can be used to activate or deactivate any functions, as well as to adjust parameterization, without specialist programming knowledge. Thanks to an integrated calibration function, the clutch control can be perfectly adapted to any drivetrain. Recalibration is automatic, and current clutch status is visualized on the GBX-A terminal.

The REINTJES system also logs historical data on request, paving the way for condition monitoring and the development of an optimized maintenance strategy. For example, gear changes can be analyzed and compared within the same fleet to optimize vessel operation and maintenance schedules.

REINTJES uses Bachmann’s proportional valve amplifier, the PVA204. Up to 20 interpolation points are available for characteristic curve correction per coil, which enables highly accurate linearization. “For the perfect component fit, we needed to adapt the PVA module firmware. And Bachmann took care of it for us,” says Norman Klippel.