Bachmann supports the development in the shipping sector

When it comes to the technological developments of the future, it is impossible to avoid the term “digital twins”. Just a buzzword? Not at all. Maritime industry thought leaders are already using digital twins to develop solutions faster, improve safety and optimize usability.

Digital twins are already part of daily business at Bachmann. Numerous applications have been implemented with the automation specialist’s controllers in recent years. The M200 controller has proven to be highly suitable for digital twins.

Here is a small selection of projects for the development of digital twins in which Bachmann is involved:

MARIN Zero Emission Lab: Digital and Physical Reproduction

The Maritime Research Institute Netherlands (MARIN) conducts hydrodynamic and nautical research together with industry. As well as studies using wave generators in water tanks, MARIN also uses digital twins to model a variety of mechanical, electrical, control and hydrodynamic processes in its Zero Emission Lab. Among other things, the institute is researching the impact of alternative fuels and new energy storage concepts on overall ship design. Existing control strategies are also tested virtually for their suitability in different wave conditions. If necessary, MARIN constructs a real-world model ship to validate results in a water tank.

Controllab: Virtual reality

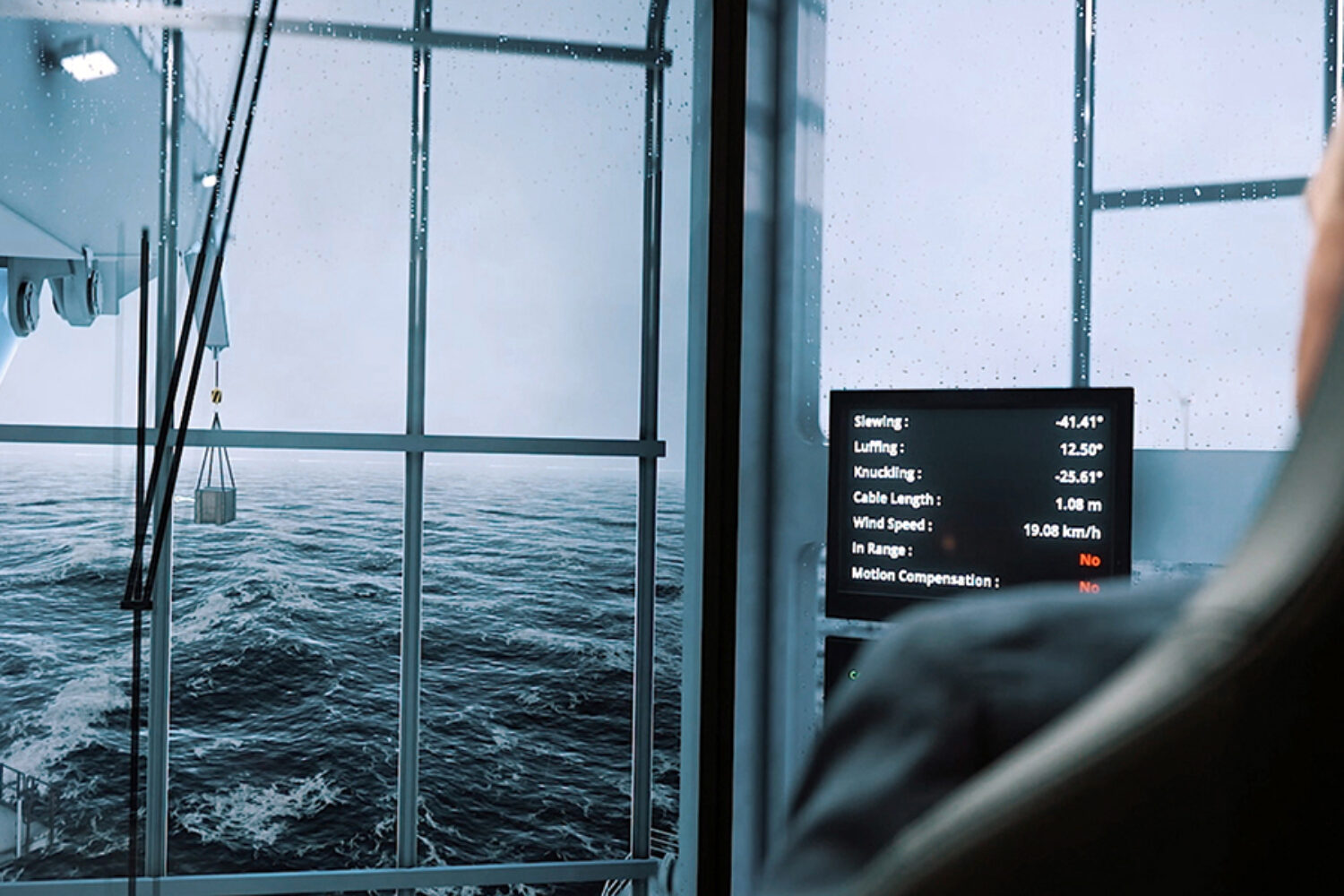

With the help of game engines, Controllab software simulates the behavior of high-tech offshore and operating equipment in elaborately-designed virtual 3D worlds. Following extensive hardware-in-the-loop testing, the control and design of robots, motion-compensated landing bridges, cranes, and many other applications are perfected with digital twins before being transferred to real world applications.

MSA Service: A transparent past

MSA-Service supports its customers in the wind and maritime industries with customized electrotechnical solutions for their automation projects. The company uses digital twins to look back in time: MSA-Service’s Multiped software collects a huge amount of existing ship data and uses it to create a digital model. With this, specialists analyze possible causes of past incidents and then derive measures to improve future developments.

VSE Industrial Automation: Quick commissioning

VSE conducts process automation and optimization in a wide variety of sectors. Together with Controllab, the company equipped an existing towing carriage at the Hydraulics Laboratory in Antwerp (Belgium) with a new controller system to track the movements of a model ship in a towing tank. The accuracy of the steering, safety and control systems could be extensively tested with the digital twin without removing the towing carriage from service.

It was also possible to model extreme conditions normally only encountered in the event of a disaster. Thanks to the simulation, damage due to undesired controller behavior could be prevented. Commissioning was completed within one week – an enormous difference from the six weeks required without a digital twin.