The Swiss turbocharger manufacturer Accelleron was established in 2022 following its spin-off from ABB. CEO Daniel Bischofberger explains to HANSA how the company has developed since then.

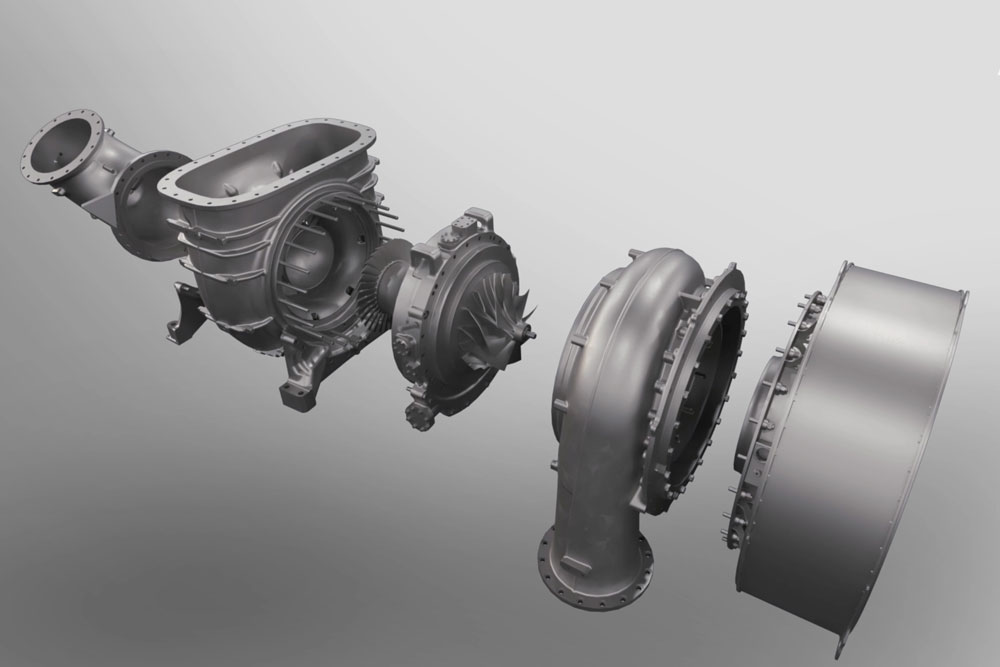

Turbochargers have been manufactured in Baden, Switzerland, for more than 100 years. Their main users are power plants and the shipping industry. Installed in large engines, they deliver more power and efficiency.

Daniel Bischofberger has been CEO of the company for around three years. Accelleron employs some 3,000 people in around 50 countries worldwide. He explains how the company has evolved since its creation and what the latest trends in turbocharging technology are.

The turbocharger business, which now trades under the name Accelleron, was spun off from ABB in 2022. What challenges did that involve, and how has the company developed since then?

Bischofberger: After separating from the large industrial group, we were suddenly a mid-sized company. As such, we wanted to be lean and agile. We had to change many things, and parts of the organisation had to reinvent themselves. We already had operations, procurement, R&D and production in-house. But the so-called “shared services” – finance, HR or IT – all had to be built up from scratch.

In addition, there was the question of market positioning. You have to imagine: we didn’t exist before. As a new, unknown company about to go public, we had to convince investors – despite operating in the combustion engine business for shipping. In Switzerland, when people think of shipping, they picture a paddle steamer on Lake Lucerne – and that’s often where the horizon ends. Likewise, combustion engines are mostly associated with cars, which are increasingly expected to be battery-electric in future. That meant we had to convince the wider community and the media that we were not riding off into the sunset, and that we don’t just have a 100-year past behind us but also a 100-year future ahead.

On the other hand, we took full advantage of our new freedom. Our idea was not to simply continue the business as we had done for the past century under ABB. Decarbonisation opens up many opportunities for us. Since the spin-off we have made three acquisitions: two in fuel injection and one in digital solutions.

At the same time, we celebrated our centenary. Our company actually invented the turbocharger – the patent was registered in 1905. By 1924 we had developed, built and delivered the first commercial turbocharger. I would sum up the last three years as follows: “It’s a once-in-a-lifetime experience. Thankfully it’s only once in a lifetime.” (laughs)

You took Accelleron public in October 2022. How have the shares performed since then?

Bischofberger: We were one of the most successful IPOs ever on the Swiss Stock Exchange, and we have since multiplied our share price.

How would you define Accelleron’s current position in the global market?

Bischofberger: In turbocharging we are the clear world market leader with a market share of around 50%. Our turbochargers are primarily used in shipping and in power generation. In fuel injection we are also a leader, particularly when it comes to two-stroke injection, and we are well positioned in the medium-speed segment and in the digital space.

What are Accelleron’s plans for the future?

Bischofberger: The markets we serve have all committed to “Net Zero by 2050”. For our turbochargers, this means the focus will increasingly be not just on efficiency but also on reducing CO₂. In turbocharging and injection we are deeply engaged in solutions for new, more sustainable fuels. Efficiency gains alone will not deliver Net Zero.

Many engines today are dual-fuel, able to burn both conventional fuels and alternatives such as methanol, ammonia or LNG. The first commercial methanol-fuelled vessel, for example, is fitted with our turbocharger. Soon, two new ammonia-fuelled containerships will enter service – also equipped with Accelleron turbochargers, and we supplied the injection systems as well. Each of these fuels has its own challenges, and we adapt our turbochargers and injection systems accordingly.

Does that mean you need a different turbocharger for each fuel?

Bischofberger: No. We have a core turbocharger platform, where only certain parts are adapted. Our turbochargers and production processes are modular. Soon we will also launch the ACCX300-L, a new turbocharger for the two-stroke segment. It offers even greater flexibility – both in terms of fuels and power range. Ships used to be optimised for a fixed operating point. Today, operators don’t always know what load profile the vessel will actually see. Our new turbocharger can flexibly adapt to the required power.

Another innovation: we didn’t make it bigger. The old rule was: the larger the turbocharger, the better the efficiency. Now, we have made the next model smaller – while still extracting more performance. It works like a cartridge system: for maintenance, the core can be removed and replaced with a new or reconditioned cartridge. The vessel doesn’t have to go into drydock – the exchange can be carried out during port calls. Turbocharger out, turbocharger in – and operations continue.

What role does digitalisation play for Accelleron?

Bischofberger: A very big one. Digitalisation is enormously important for our internal processes. We have around 600 service engineers worldwide at about 100 locations. When problems occur on board during service, they can, for instance, use artificial intelligence to analyse historic service reports and identify potential solutions.

Externally, we offer customers software-as-a-service – for example, condition-based and predictive maintenance. Since our acquisition of True North Marine, we have also added weather routing and voyage optimisation. Ships are highly complex systems. We want to understand where inefficiencies lie and where optimisation potential exists – to identify the best route with the lowest fuel consumption.

Doesn’t that take you away from your core business?

Bischofberger: Not at all. If you look at our core business, it’s about helping our customers decarbonise their vessels. Many other companies have the same goal, but they often come from the digital side, focusing on algorithms. Our advantage is that we come from the technical side and add algorithms to it. We understand engines and turbochargers. For us, it’s not just bits and bytes. We know how the engine and turbocharger should ideally operate – that is our strength.

We also see growing demand from customers for digital solutions. Ships used to be simpler. With new fuels such as ammonia and methanol, and with the use of wind-assist systems, complexity on board is increasing. At the same time, crew expertise is declining as fewer engineers go to sea. With our expanding digital portfolio, we can support customers more effectively in boosting efficiency and reducing emissions.

By Anna Wroblewski